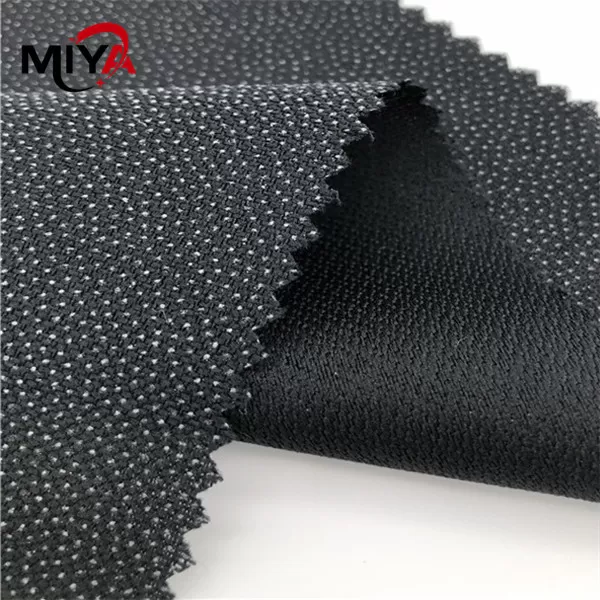

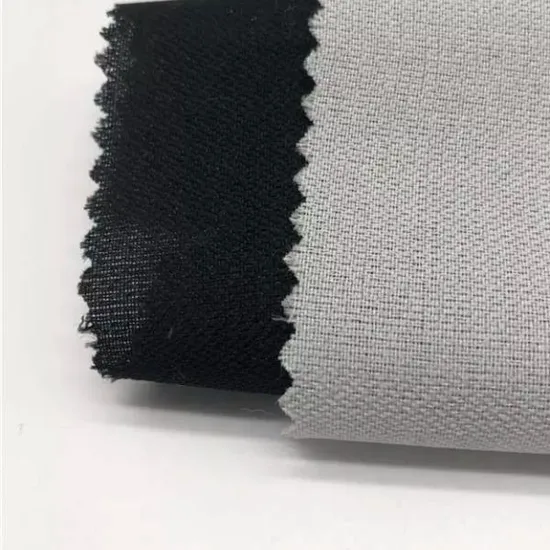

Waterjet Fabric

Special nonwoven fabric produced with high-pressure waterjet technology

Waterjet Fabric Features

Key Features

Physical Properties

- Grammage: 40-200 g/m²

- Width: 10-320 cm

- Color: Standard and custom color options

Performance Properties

- High cutting precision

- Heat-resistant structure

- Chemical resistance

Production Process

1. Material Selection

Selection and preparation of appropriate fabric type

2. CAD Design

Creation of digital design for cutting

3. Waterjet Cutting

Precise cutting with high-pressure waterjet

4. Edge Processing

Trimming of cut edges

5. Quality Control

Detailed inspection of the product

6. Packaging

Packaging according to customer requirements

Advantages

Precise Cutting

Millimetric precision cutting can be achieved with high-pressure waterjet.

No Heat Effect

No heat is generated during cutting, preserving material properties.

Multi-Layer Cutting

Multiple layers can be cut in a single pass.

Environmentally Friendly

No chemical waste is generated, and water can be recycled.

Technical Specifications

Material Type

Polyester, Nylon, Aramid, Composite

Grammage Range

40-200 g/m²

Width

10-320 cm

Cutting Precision

±0.1 mm

Maximum Cutting Thickness

Up to 150 mm

Water Pressure

Up to 6000 bar

Waterjet Fabric Usage Areas

Automotive Industry

Used in automotive interior upholstery, airbag fabrics, and other automotive textiles.

Aerospace

Offers cutting solutions for aircraft interior upholstery and composite materials.

Medical Products

Used for precise cutting of surgical drapes and implant fabrics.

Industrial Filters

Preferred for cutting high-performance filter fabrics.

Architectural Textiles

Custom cuts can be made for building facades and sunshade systems.

Defense Industry

Used for ballistic protection fabrics and military equipment.

Waterjet Fotoğrafları

Our Other Products